Feb 20 2024

Oh ya there’s more we have only started.

#6: Old Tilt trailer. Nov 2018: There was a pause on the Acorn trailer till the winter of 2018. And what do you know a friend gives me an old tilt trailer. So I quickly made it nice and new again.

Boy I’m turning them out… Sold it quickly too. Modified the frame, new wheels, new lights and new deck. And I painted it an interesting color.

#7: Side by side trailer. March 2019. The Acorn trailer is now gone and this winter I traded my quad for a side by side. It does not fit in my 4×8 trailer. So I found this one made from a double jet ski trailer.

It was nice and wide but a tad short . So I added that mesh part and ramps at the back. Everything else was good to go. I think I only used it for one season.

#8: Scooby Trailer. June 2019. As was the case often I got a free trailer. I had a ten foot camper that did not fit my truck.. Sooo this 18 ft travel trailer frame was perfect to make what we call a “scooby”. Long story behind the name so lets just say we built the trailer to hold the camper.

And look a quad fits the front. I used this rig for one fall camping. The camper was in amazing condition. Post for that.. Frontier . I sold it the next spring.

#9: 18 ft Flat deck. June 2019. Another free travel trailer ! This one was in the flood so the travel part was toast. There was a free place at the land fill for flooded RV’s so that’s where the body went. So let’s build a nice flat deck.

And I did just that. We could fit two ATV’s on it. I did a dumb thing when I sold it…Trusted the buyer to pay only half and I transferred it to him… Never saw the rest of the money. This was one of my best builds new tires, paint, new deck, heavily modified the frame. And LED lights all around.

#10: June 2020. No post for this one. new Southland ATV trailer. I thought I would treat myself to a new trailer for my ATV. But I’m including it here because I improved it just a bit… I built a custom box for the front. To hold the spare wheel and my tie downs.

Perfect for what I needed and I used it to move to Alberta.

#11: Old K mart trailer. Sept 2020. Just a cheap project to keep busy.

This is one of those folding trailers so one can stand it up for storing. I only spent a few weeks on it and sold it right away. New wheels, new paint, new deck.

#12 & 13: No post for these. Oct 2020. I was looking for more small trailers to fix up when this two for one came up. Only one registration though. One was a tilt deck for snowmobiles, the other an old funky utility trailer.

Here’s the tilt trailer that I traded to a friend ( with the registration) for the horse trailer that was handy for the move..Later.

This is the old utility came with me to Alberta and I made a boat trailer.

#14: Surf Side Trailer. Nov 2020. Free ! Abandoned and needed to be moved from my friends campground. Even though I said I wasn’t going to do another fiberglass trailer I just could not say no to this one. Very rough and FULL of stuff.

I’m thinking someone painted it green to hide it in the bush.. Another “frame off” restore, but this time I knew what I was doing. Four months later and you would never know how rough it was.

It sold just as we were packing to move. A tidy sum of money made on this one. Check out the link for the posts. I now had a reputation for restoring these trailers.

#15: The Horse Trailer. March 2021. No post for this.. but I do have photos.

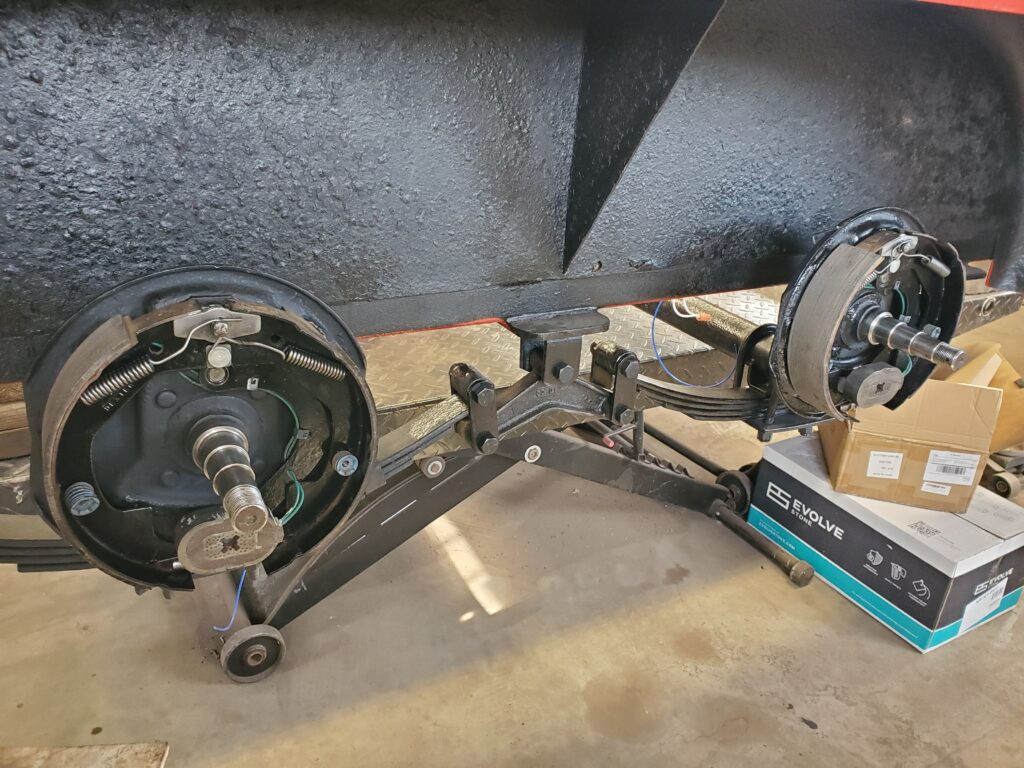

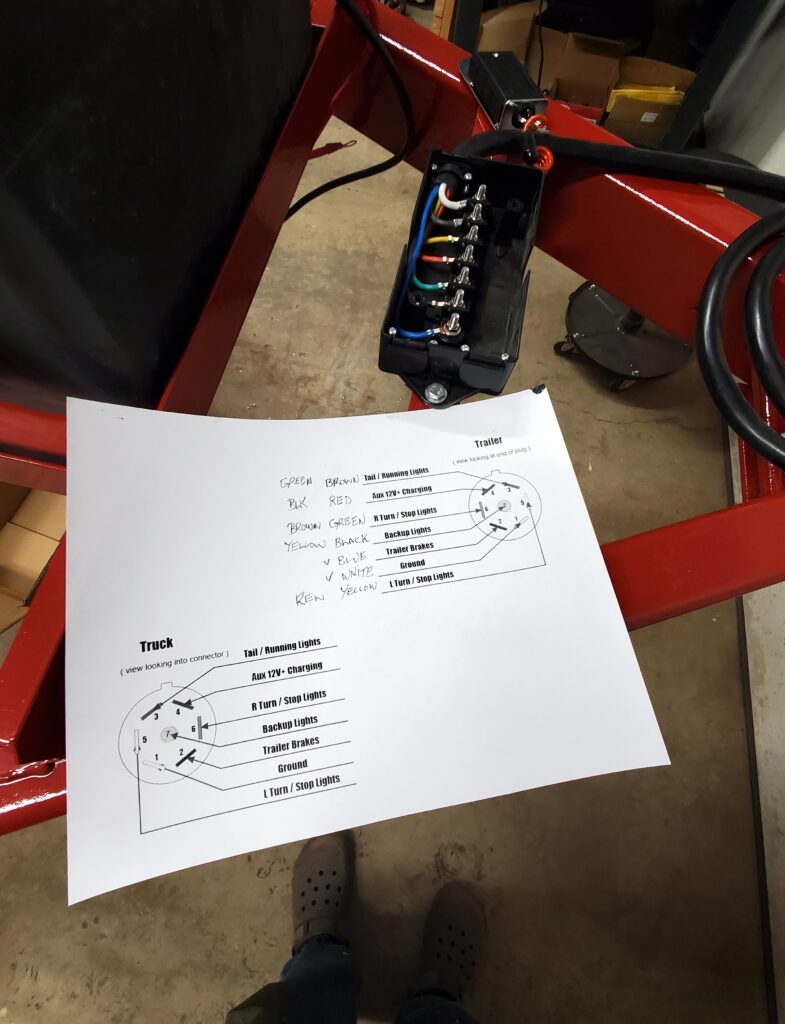

I bought this about ten years go at a bailiff auction for very cheap. It was then sold to a friend that needed it. In March I traded him back for the sled trailer. He had replaced the tires, and then I rewired the lights and got the brakes to work too. My entire shop fit in this trailer for the move to Alberta. I sold it later that year for a nice profit.

#16: Dumping Trailer. No post. Aug 2021. What the heck.. I’ll include it here because it was so nice. The house we bought here in Alberta needed major yard clean up. I was using the utility trailer but what a pain. I decided to find a dumping trailer.. Nope so I bought a new one. 5×10 ..5000 lb and had everything you needed for dump runs.

So many trips to the local landfill they recognized me each time. Lots of highway miles too. once the yard work was done in the new house I put it up for sale.

Lets start a new page because there is MORE !